Application Area

Application Area

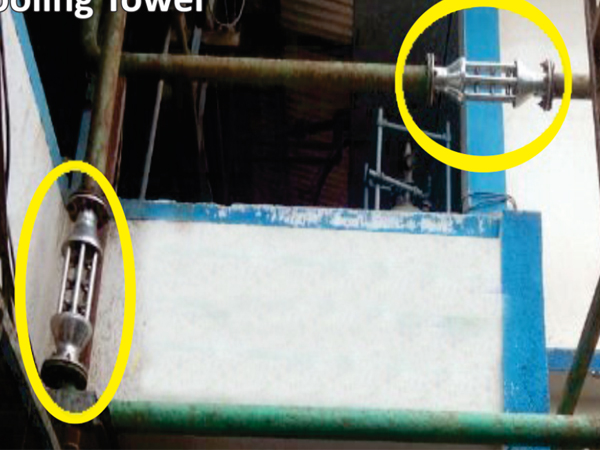

COOLING TOWERS

They are a closed water circulation system and scale build-up is very common because water is re-used. Water evaporates leaving behind impurities. Descaling is important because the buildup can result in less efficiency and eventually corrosion. MAGNACAT changes the charge of the water molecule. The surface tension of the water is decreased, which removes existing scale build-up in spray nozzles and prevents new scale formation in the system.

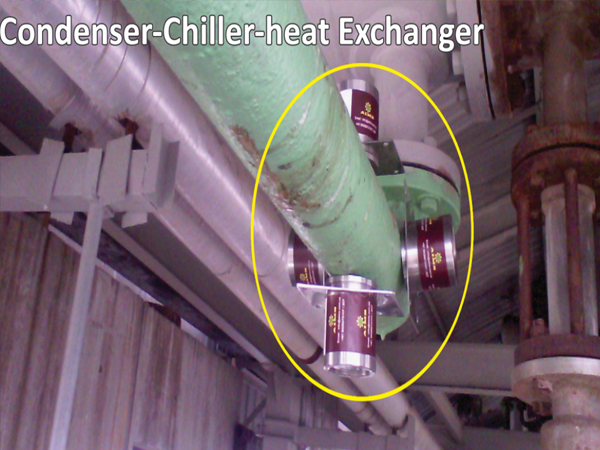

CONDENSERS, CHILLERS & HEAT EXCHANGERS

They are a closed water circulation system and scale build-up is very common because water is re-used. Water evaporates leaving behind impurities. Descaling is important because the buildup can result in less efficiency and eventually corrosion. MAGNACAT changes the charge of the water molecule. The surface tension of the water is decreased, which removes existing scale build-up in spray nozzles and prevents new scale formation in the system.

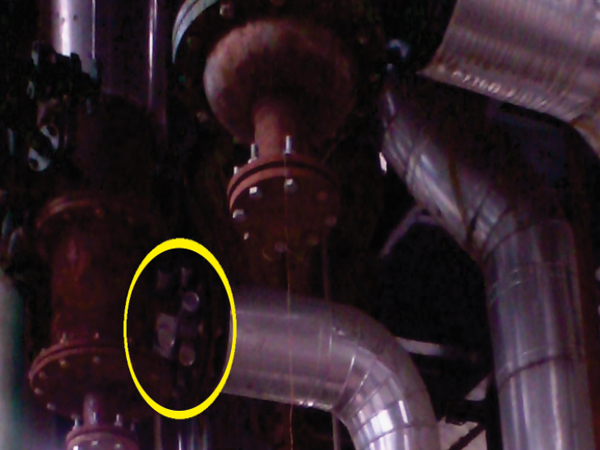

BOILERS

It is one of the-most critical equipments in industrial plants, where preventions are taken to avoid scaling issues. The available amount of dissolved solids enters the boiler through water in form of soluble solids and is precipitated on the contact surface when the concentration level increases because of evaporation. Even after the use of soft water (RO & Softening chemicals); scaling issues have been observed.

By implementing nominal modification of the route of boiler feed water system, the feed water will pass through additional RECIRCULATION system passing through our MAGNACAT, the same water will not allow scale to precipitate on the contact surface or the boiler tubes.

ETP & MEE PLANTS

They are used to convert waste water into effluent by efficiently using the heat from steam to evaporate water to get a concentrated solutions. Due to very high TDS effluent the dissolved solids get saturated and accumulated in calandria tubes. A set of MAGNACAT-(Descaler Solutions) at the the inlet of calandria in the circulation line, will charge the dissolved minerals (up to 2-LAC TDS) in such a way that the saturated minerals bonding in calandria tubes will loosen up and reduce the frequency of tube choking in MEE plant.

BOILERS

More the compressed air is cooled inside a compressor's inter-cooler and after-cooler; the compressor will become more energy-efficient and more water vapor will be condensed. In water-cooled compressors, due to hard water scaling in PHES, the heat transfer cannot take place properly and hence decreases compressor efficiency. Our compact MAGNACAT design will fit inside the compressor body near PHE or cooling water system and charge the high pressure water before entering into the cooling system which will clean the existing scale build-up from plates and will also prevent further accumulation of scale. This will eventually improve compressor efficiency using the same hard water.

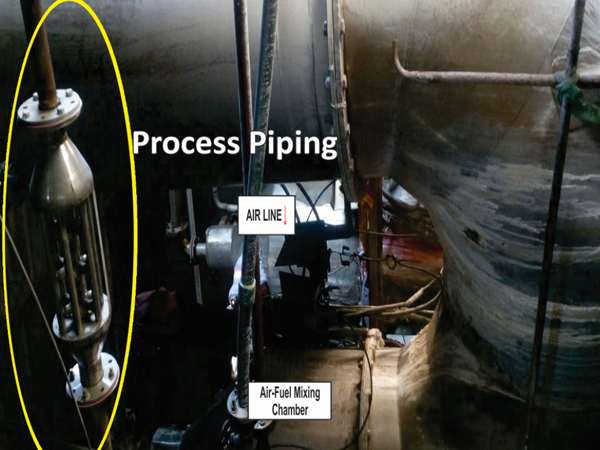

PROCESS PIPING

In pipe systems, generally cavitation occurs due to an increasing in pipe elevation and long routing of piping grids. Scaling is the most common type of fouling on pipe surface and is commonly associated with inverse solubility of salts such calcium carbonate found in water. Salts become less solute as the temperature increases and thus deposit on the pipe surface. Such scale is difficult to remove mechanically and chemical cleaning may be required.

MAGNACAT will give its best performance in such piping loops by energizing the magnetically which will change the pole of water minerals so the possibility of accumulation of inverse soluble minerals will improve over all plant efficiency and reduce the piping, valve and plumbing cost of the plant.